Transformando

la manera en la que el mundo obtiene la energía

En enero de 2022, Array Technologies adquirió STI Norland, reforzando su cadena de suministro y su expansión internacional. Array Technologies es líder global en la promoción de un futuro basado en el uso de energía limpia. Sus más de 30 años de innovación han permitido a Array consolidar la industria solar y situarse en una posición única para ofrecer soluciones de energía renovable a clientes de todo el mundo que buscan adoptar fórmulas de generación eléctrica limpia. Aunque nuestra fortaleza radica en la construcción de los seguidores solares a gran escala más fiables y eficientes del mundo, nuestra experiencia, capacidades y recursos nos permiten posicionarnos también como suministrador de soluciones en materia de energía renovable. Con un espíritu pionero, innovador y visionario, nuestro compromiso es generar energía de forma íntegra a fin de favorecer la sostenibilidad del planeta.

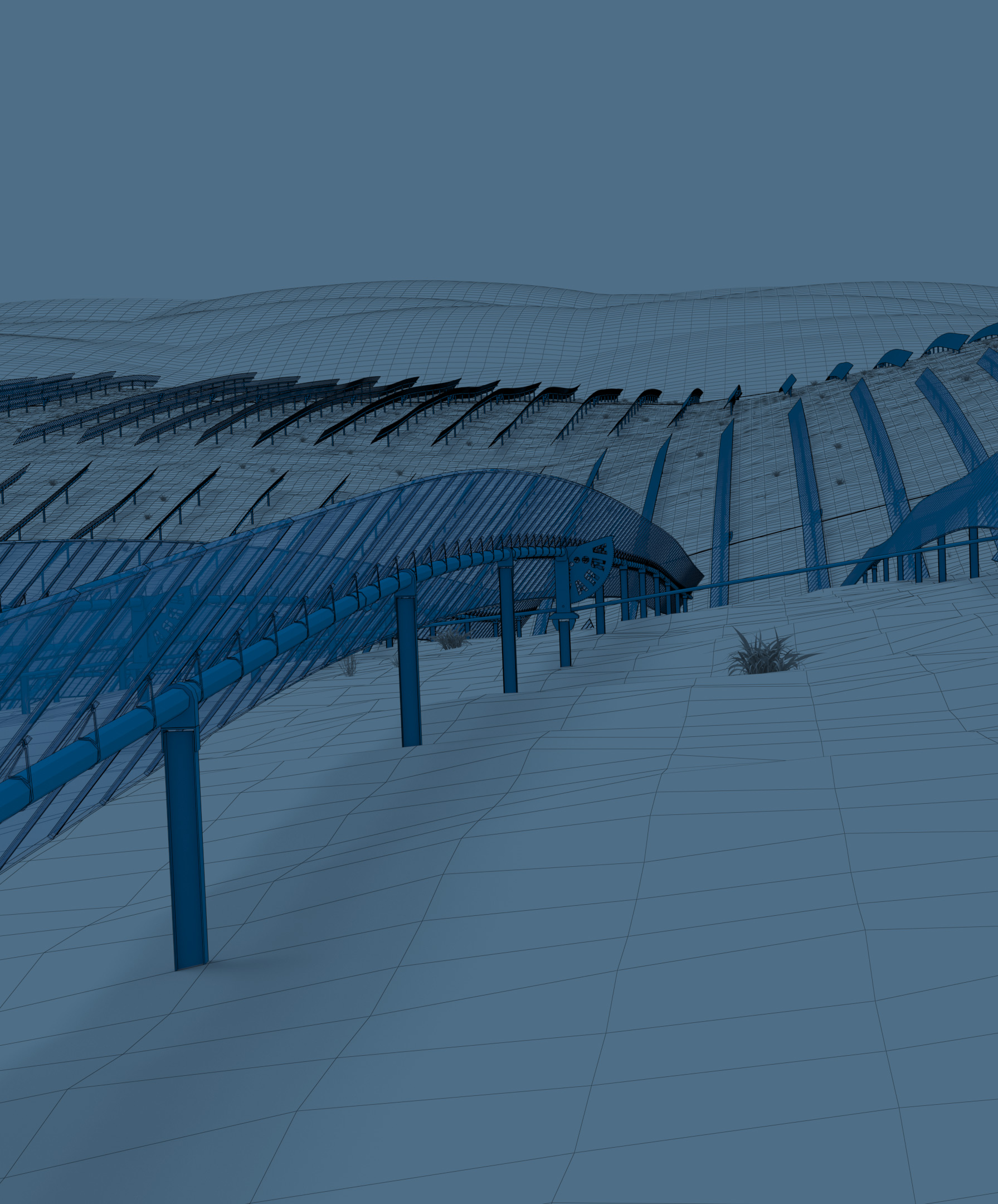

Nuestros seguidores solares están instalados en plantas de todo el mundo

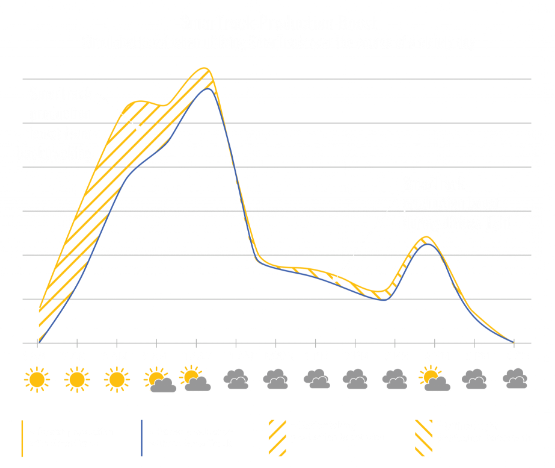

Aumente la producción y minimice su LCOE (coste normalizado de energía) gracias a esta potente plataforma informática de aprendizaje automático diseñada en exclusiva para plantas solares a gran escala.

Nuestras noticias más recientes

Energía limpia sin complicaciones

Nuestra empresa siempre ha creído que la tecnología de seguimiento solar a gran escala es fundamental si queremos asegurar un futuro sostenible. Compruebe de qué manera nos comprometemos con el crecimiento de nuestro negocio en base a los principios ESG.